| Sign In | Join Free | My chinacomputerparts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacomputerparts.com |

|

Brand Name : MCLLROY

Model Number : MCL940 ZL940

Certification : CE,ISO9001

Place of Origin : China

MOQ : 1 Set

Price : $ 4000-6000 /Unit

Payment Terms : 30% T / T in advance and 70% balance before shipment Or 100% L/C at sight

Supply Ability : 100 sets / month

Delivery Time : 5-8 working days

Packaging Details : Nude ,3 Sets Fasten Packing in 1 40HQ

Rated power : 76kw

Rated Load : 2200kg

Dumping height : 3500mm

Bucket Capacity : 1.2m3

Overall Size (L*W*H) : 6330*2170*3080mm

Max.Dump Clearance : 3500mm

Emissions : EU Stage II

Operating Weight : 6100 kg

Max. Travel Speed : 28 km/h

Gear Box : CVT 280 torque converter

Axle : Large hub

Axle Base : 2560 mm

Brake : Air Brake

Hydraulic Cycle time - lift : ≤ 6 s

Min. Ground Clearance : 400 mm

Wheel Base : 1640 mm

Dump Reach : ≤ 650 mm

Overall Length - With Bucket : 6240 mm

Overall Width : 2040 mm

Overall Height : 2830 mm

Tyre Size : 1670-24

Breakout Force : 52 KN

1. Products Description

In general, for construction machinery, the four most important factors are: price, quality, operation, and after-sales.

The amount of shovel material and the stability of the loader depend on the cooperation of the loader frame.

The flexibility and light operation mainly depends on the hydraulic system of the loader.

The low failure rate depends on quality as well as the after-sales service.

MCLLROY wheel Loaders are widely used in the construction, municipal engineering, urban and rural gardens, lime, sand, cement factories, mines and other enterprises and institutions and departments. It is particularity applied to the narrow space for the loading operation of stone,sand and other construction materials.

2. Specification

| MODEL | MCL 940 | |

| ENGINE | Engine Model | Yun Nei 4102 Supercharged |

| RPM | 2400 | |

| Rated Power | 76 kW | |

| Emissions | EU Stage II | |

| WEIGHTS | Operating Weight | 6100 kg |

| Rated Load | 2800 kg | |

| BUCKETS | Bucket Capacities | 1.2 m³ |

| TRANSMISSION | Max. Travel Speed | 28 km/h |

| Gear Box | CVT 280 torque converter | |

| Axle | Large hub | |

| Axle Base | 2560 mm | |

| Brake | Air Brake | |

| HYDRAULIC SYSTEM | Hydraulic Cycle time - lift | ≤ 6 s |

| DIMENSIONS(APPROXIMATE) | Min. Ground Clearance | 400 mm |

| Wheel Base | 1640 mm | |

| Reach at Max.Dump Height | 3500 mm | |

| Dump Reach | ≤ 650 mm | |

| Overall Length - With Bucket | 6240 mm | |

| Overall Width | 2040 mm | |

| Overall Height | 2830 mm | |

| OPERATING SPECIFICATIONS | Tyre Size | 1670-24 |

| Breakout Force | 52 KN | |

| Joystick | Machanical | |

| Min. turning radius | ≤ 6200 mm | |

| STANDARD EQUIPMENT | Hour meter | Yes |

| Tool Box | Yes | |

| Dual Hight&Low Speed Handle | Yes | |

| OPTIONAL EQUIPMENT | Air Conditioning/heater | Option |

| Quick Change | Option | |

| Multifunctional Attachment | Option | |

| Hydraulic Pilot | Option | |

3. Details and Advantages

The main components of the loader are used brand-name manufacturer's products, interchangeability of good, reliable, well-resourced parts.

1) Engine:Domestic famous engines ,green/turbocharged/inter-cooled engine.

2) Transmission:Wet multi-plate clutch automatic transmission ,torque converter ,stable performance ,famous brand in China.

3) Axle: Heavy-duty axle ,planetary reduction ,solid and durable ,with the corresponding tires ,for the loader to provide.

4) Hydraulic system:High Efficiency and energy conservation patented dual-pump confluence technology .

5) Tire:38% Rubber content tire,Wider off-road tire

6) Frame:The newest design ,small center precision turning radius, stable and thickened frame,strong and durable.

7) Cab:

I. Radio.

II. Air conditioner.

III. Central electrical control box for easier servicing.

VI. Hydraulic brake system gas cap,caliper disc brake.

8) Gull-wing Engine Doors make access and daily maintenance easy.

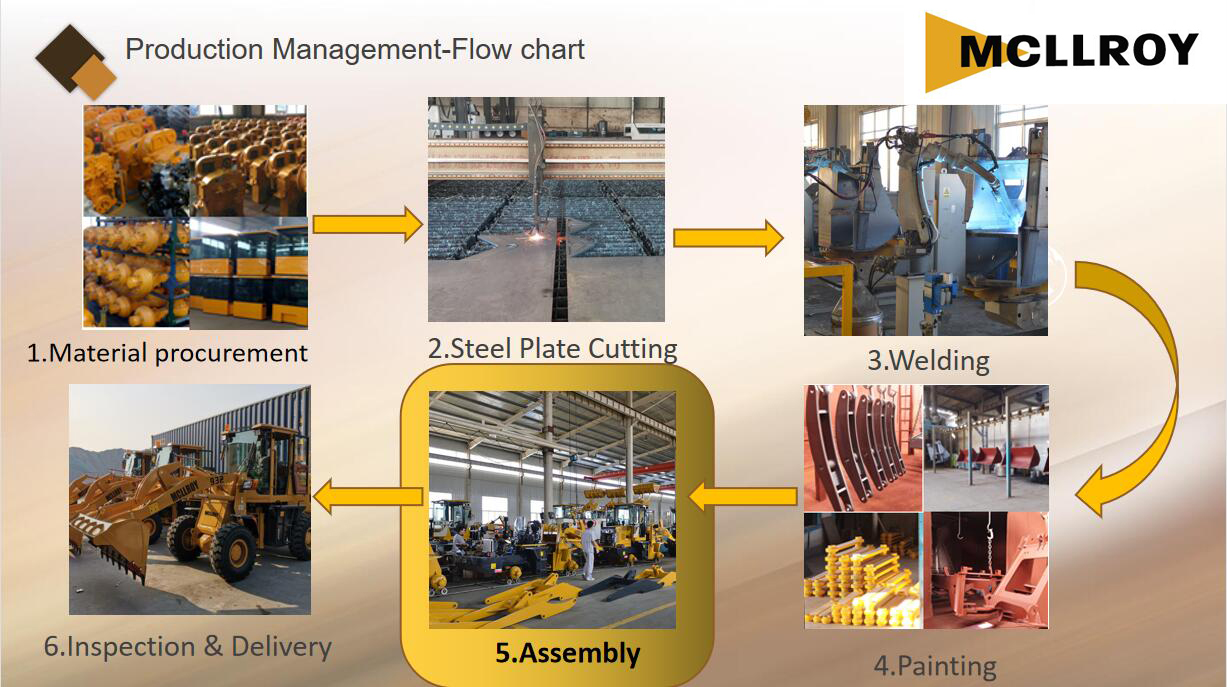

4.Production lines:

A complete production process mainly includes: material procurement-steel plate cutting-welding-spray painting -drying-assembly-inspection

Assembly:

Our factory arrange seven steps for assembly. There are over a thousand parts in a loader. I will talk about assembly of major components.

The second step is connecting engine and gearbox, then the third step must be putting them onto the frame.

Put engine on the frame, connect the priority valve, install radiator and water tank;

Add hydraulic transmission oil to the gearbox (add gear oil for mechanical transmission), install the hydraulic transmission oil radiator and pipeline, install the hydraulic oil radiator (the pipeline does not need to be connected), connect the brake caliper pipeline, brake pipeline, connect main reduction (differential) drive shaft.

There are quite so many pipelines here, this step could use many screws and clamps.

In this step, first of all, we must pay attention to the four feet of the frame where the engine is fixed, they have to be level, otherwise, the force is uneven, and there is a risk of cracking in the engine and gearbox housing; and the connection point of the radiator must be fixed with sealant; and then see if the clamp is tight; whether the screws of the transmission shaft are tightened.

2-3 workers will be in charge of this step.

hydraulic wheel loader

small front end loaders

mining front end loader

agricultural wheel loader

heavy machinery loader

|

|

OEM Hydraulic Wheel Loader 6100kg 650mm Dump Reach Images |